Newscenter

Newscenter

-

Notice of Partnership and Agency Authorization

03-19-2025Notice of Partnership and Agency Authorization

We are pleased to announce that, since June 2024, FONDA PUMPS has officially entered into a partnership with Syndicated Industries Inc. of Canada. As part of this strategic alliance, FONDA PUMPS has appointed Syndicated Pumps, a subsidiary of Syndicated Industries Inc., as the exclusive distributor of FONDA PUMPS products in Canada.

Under this arrangement, Syndicated Pumps is authorized to conduct sales and provide services within the scope of its appointed mandate. This strategic move is aimed at bringing more efficient and convenient services to our valued customers across Canada.

We believe that this collaboration will create a win - win situation, further strengthening our market presence and enabling us to better serve your needs.

Thank you for your continued support.

FONDA PUMPS -

Fonda Pump Delivery

04-25-2022From the beginning of March, our factory was suffered a locked-down due to continuous impact of Covid-19,which led to huge postpone of delivery to most of our customers.In such a severe situation,our factory extend work time and made concerted effect to speed up the earliest delivery after the resume.

Last week, 26 sets of centrifugal pumps have been successfully completed the loading in the factory. These pumps are fully in compliance with API610 standard and inspected by the end user prior to the loading.

During the epidemic, we insist on supplying guaranteed quality pump equipments and professional technical support to our customers for their urgent demand.

We will win the war without gunpowder!

-

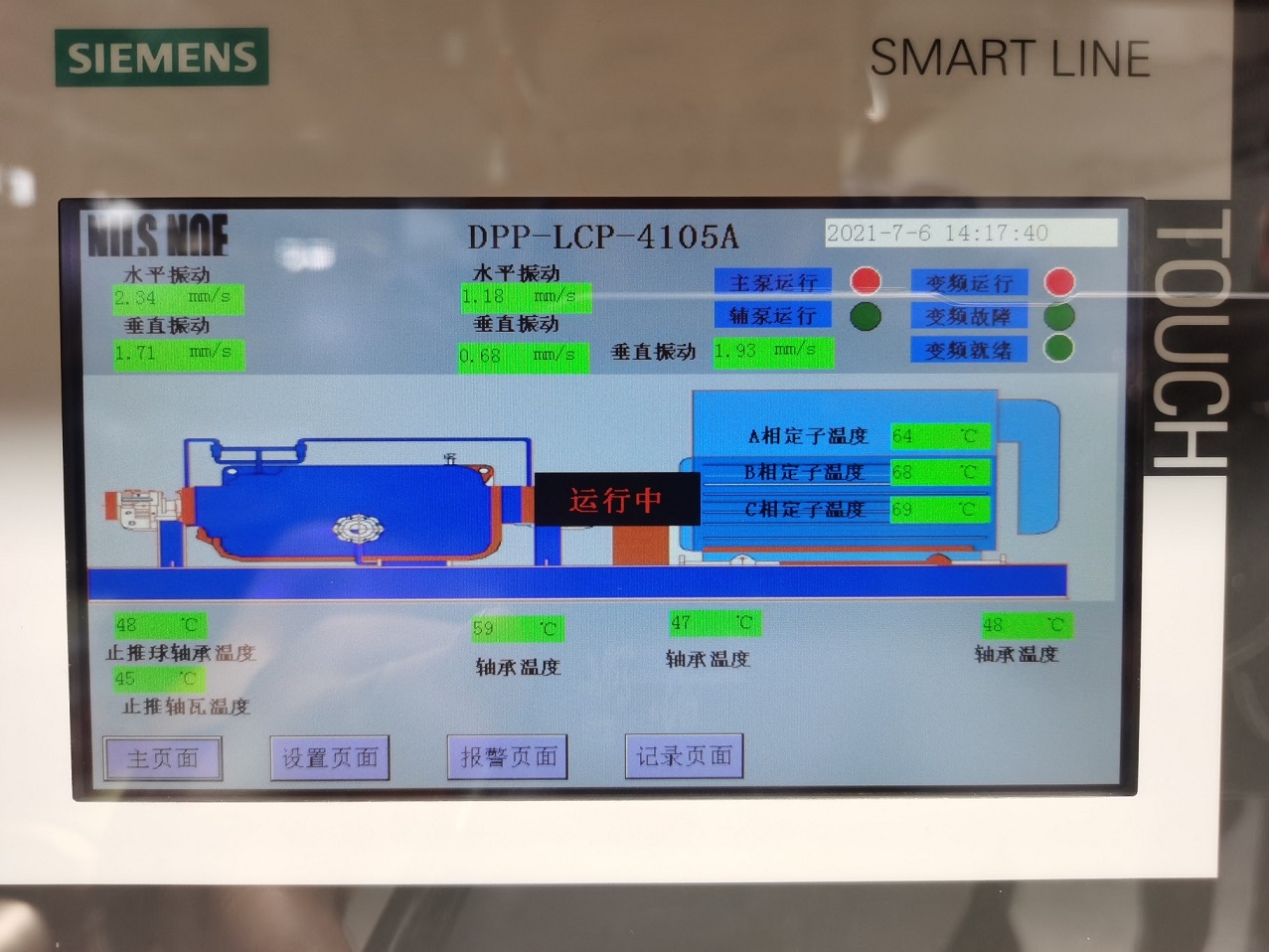

Water Injection Pumps (API610 BB3) for CNOOC offshore platform

07-29-2021We are proud to announce that we completed the tests and delivery of 3 sets of multistage pump packages in last few weeks. These pumps are the main water injection pumps for CNOOC offshore platform in LF15-1 oil field. The delivery includes complete pump packages, spares and VFD cabinets.

Pumps are designed in full compliance with API610 standard and made in duplex steel (D-1). They were tested with 10KV high voltage motor/710kw through VFD control and hydro-tested at the pressure of 225bar for one hour.

During the performance test and 4-hour mechanical run test, all parameters are found satisfactory. Especially, the vibration of the pump is observed in very low level. The end user is also happy with the NPSH test result.

-

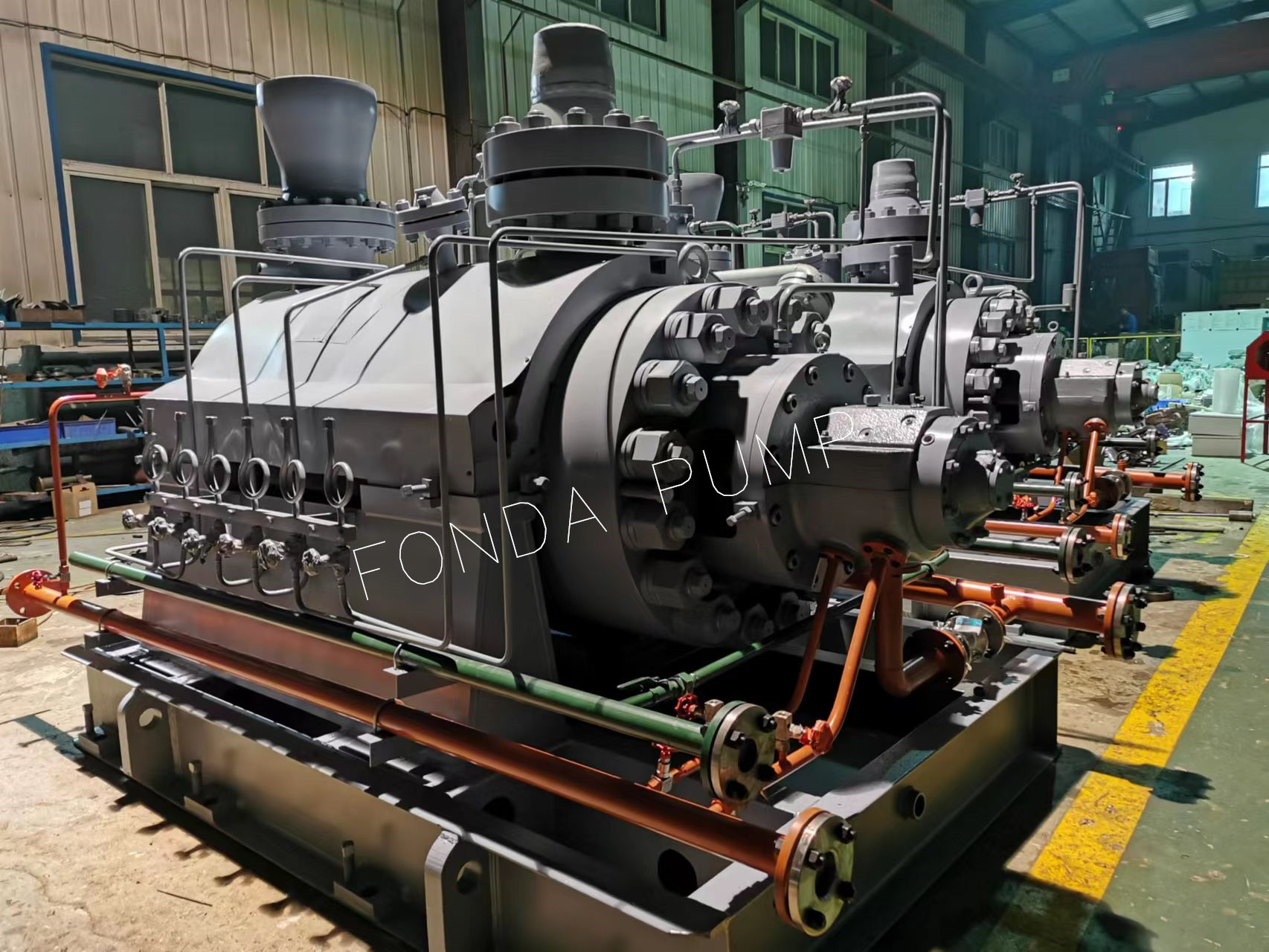

Crude oil pumps for Sonatrach

07-22-2020Two crude oil pumps have been successfully tested in May and completed the delivery recently. Both pumps are API 610 11th edition compliant.

The BB3 pump(7 stages) has a double suction impeller with rated flow of 400m3/h and diff pressure of 1230psi. The pump has been tested with high efficiency of 76%, the job motor is rated at 1400kw. The whole skid package is 8.6meter in length and 2.3meter in wideth. Typically, the pump is designed to meet varies of operation conditions through a hydraulic coupling ( speed variator). Seal flush system plan-31+66B ensures a systamic safety of mechanical seals.

The BB2 pump (2 stage) has the rated flow of 250 m3/h and diff pressure of 540 psi. The pump is equipped a motor of 500kw and operated to meet different operation conditions through a hydraulic coupling ( speed aviator). The skid package dimensions is 6.3 meter (L) x 1.8 meter (W). Pump is made of carbon steel per material level of S-6. After 4 hours mechanical run with witness of TPI, the pump has been verified in good performance.

辽公网安备 21011402000387号

辽公网安备 21011402000387号